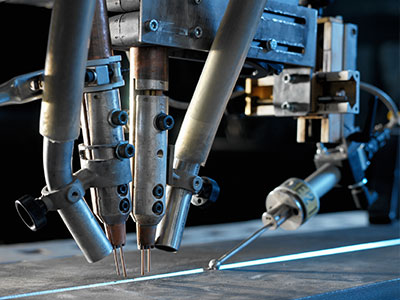

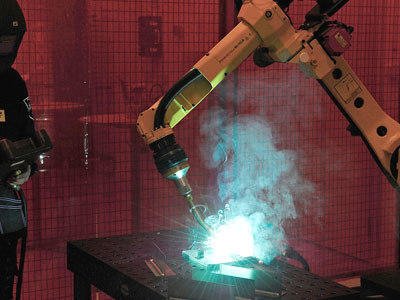

Welding automation and robotization

One of the most diverse product lines among the major welding equipment suppliers allows Sahel Gaz to serve all major industrial sectors.

When a “critical weld” is needed, Sahel Gaz can provide the solution.